- Home

- About Us

- Products

- Gallery

- International Collaboration

- Location We Serve

- Clients

- Download

- Contact

- Enquiry

To protect the environment from waste foundry sand and to make easy availability of raw sand into the system, thermal reclamation of the sand is the best option.

Foresighting the need of quality product in thermal reclamation, ganesh quality machine has joined hands with German manufacturer Förder - und Anlagentechnik GmbH (FAT), founded in 1973, and acting as plant manufacturer worldwide.

FAT is characterised by quality, technological progress with ground-breaking developments and a well thought-out customer service strategy.

Thermal reclamation : reclaim with new sand quality

Environmental protection, sparing use of raw materials

resources and higher demands on casting quality make a

continuous improvement in processes necessary. Because

of this economical, reasonable and sustainable recycling is

becoming more and more important.

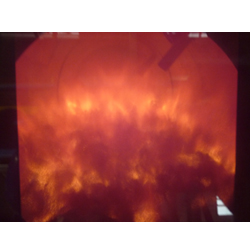

By using the thermal reclamation plant rests of organic binder,

which have still remained on the sand grain, get burned away.

Due to the low height of the sand layer within the oven,

every sand grain has contact to the flame at all times and

the German rule concerning the exhaust gases "TA-Luft" is

observed. Also fine sands can be reclaimed.

The produced reclaim has a loss of ignition of up to 0,1%.

The installation of the FAT thermal reclamation plant offers

the following advantages to our customers :

a) In the by pass, generating new sand from reclaim. This

generated new sand can be added flexibly to the reclaim,

which means a reduction in total loss of ignition (LOI)

within the sand system

b) Treating used sand, which used to be discarded, in the way

that the thermal reclaimed sand can be used as new sand

Cost reduction by thermal reclamation

The FAT thermal reclamation plant is the possibility to

minimize the part of new sand as well as the quantity of

used sand to be landfilled. In this way the acquisition

costs for new sand and the disposal costs for used sand

can be reduced by up to 95%.

Your savings potential per year :

To generate new sand from excess used sand!

With assumed costs of

40 € per t new sand and

40 € per t expenditure on disposal

thermal reclamation allows for a potential of savings for

8 t new sand per day - approx. 100.000 €/year

16 t new sand per day - approx. 240.000 €/year

30 t new sand per day - approx. 480.000 €/year

Further advantages of the application of thermal reclaim :

• higher size accuracy of castings

• better casting surface

• lower fettling effort

• less waste

• lower demand for binders